Logistics transportation stands as an essential sector in the global economy, facilitating the movement of goods across supply chains. Hence, the maintenance of vehicles and logistics equipment is pivotal within this sector, as a breakdown can lead to significant delays and costs for companies.

Traditional maintenance, relying on periodic inspections, might overlook wear and tear or details that could eventually result in unexpected costs, productivity losses, downtime, and equipment damage. On the contrary, predictive maintenance employs artificial intelligence to gather and analyze real-time data. This enables companies to identify potential issues before they escalate into breakdowns.

This article delves into what predictive maintenance is and how it can benefit companies in this sector.

What is Predictive Maintenance in Logistics Transportation?

The demand for freight units exposes them to high wear and tear due to transit times. As each trip generates revenue, minimizing downtime becomes crucial. Hence, maintenance plays a pivotal role in operations.

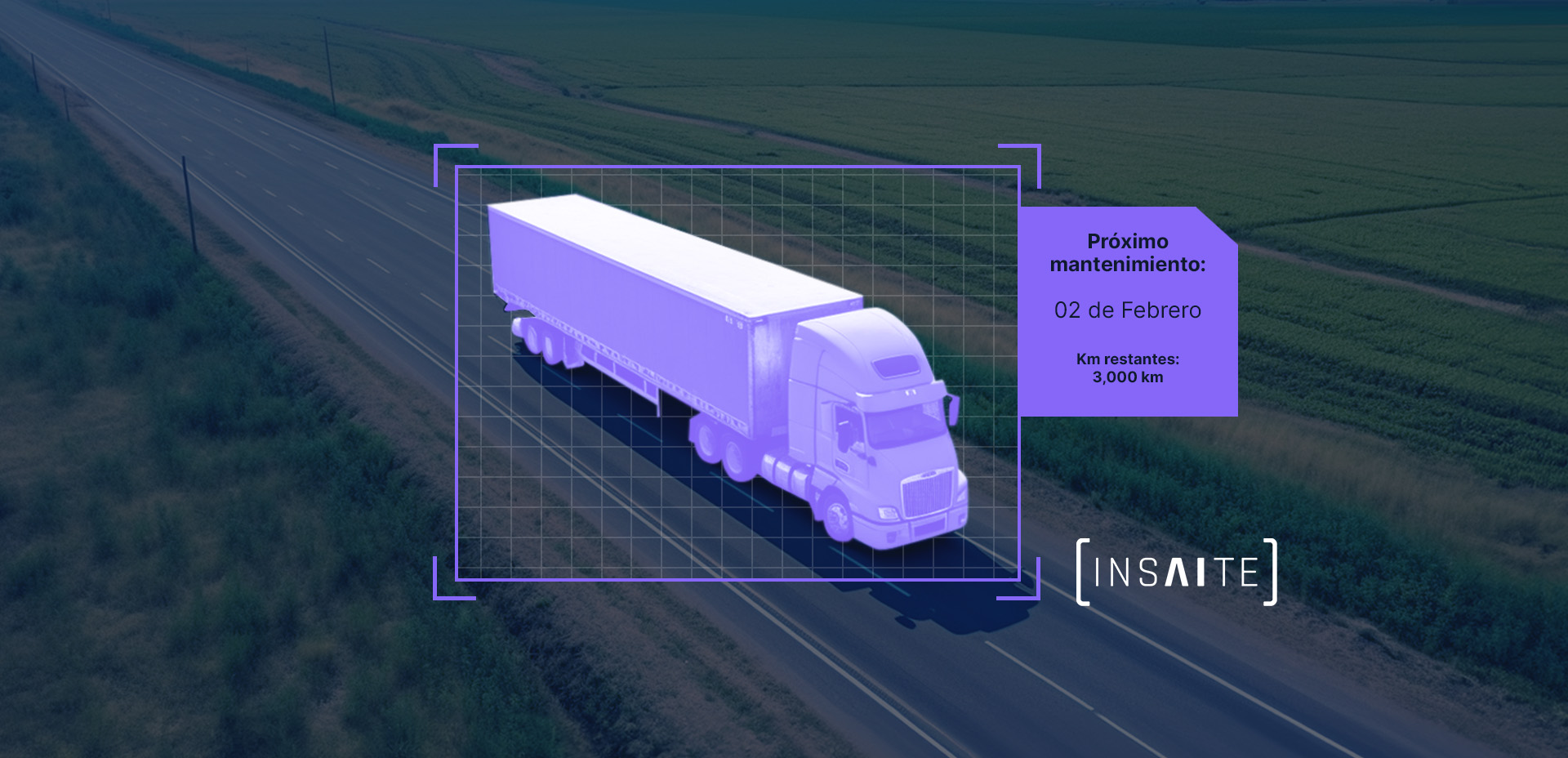

Predictive maintenance is a technique employing AI to collect and analyze real-time data from vehicles and transportation equipment. This data may include:

- Sensor information such as vibrations, temperature, or pressure.

- Telemetry data like speed, mileage, or fuel usage.

- Historical maintenance data like replaced parts or repairs undertaken.

Analyzing this data allows the identification of potential problems before they evolve into significant breakdowns affecting cargo operations and transit.

Advantages of Predictive Maintenance in Logistics Transportation

Predictive maintenance in logistics transportation offers several advantages, including:

- Cost Reduction: Assisting companies in reducing maintenance costs by 20-40% by anticipating and addressing breakdowns, thereby reducing downtime and equipment damage.

- Enhanced Reliability: Increasing the reliability of vehicles and cargo equipment by proactively identifying and addressing potential issues.

- Improved Safety: Enhancing operational safety by preventing breakdowns, thus reducing the risk of accidents.

Applications of Predictive Maintenance in Logistics Transportation

Within the freight transport sector, predictive maintenance can be applied at different levels and across various types of units used for material mobility:

- Trucks: Predicting wear and tear on tires, brakes, engines, and other components, including trailers, ensuring compliance with traffic regulations and preventing breakdowns.

- Planes: Implementing predictive systems to anticipate engine, turbine, electrical system, and other component wear, ensuring aircraft safety and operation.

- Trains: Utilizing predictive maintenance to forecast wear on wheels, brakes, engines, containers, among other elements, to avoid intermodal operation delays.

- Ships: Using predictive maintenance to anticipate wear on propellers, engines, electrical systems, containers, ship structure, among other elements.

Implementing Predictive Maintenance in Logistics Transportation

To implement predictive maintenance, real-time data collection and analysis are crucial for a comprehensive overview of operations. This can be achieved through sensors, telemetry, or historical maintenance data. Once gathered, AI algorithms should analyze these data sets to identify patterns and trends indicating potential short, medium, or long-term issues.

Based on these predictions, developing a maintenance plan is essential, encompassing necessary actions to prevent or repair potential problems and reaction times, aiming to minimize unit downtime.

Conclusions

In conclusion, the adoption of predictive maintenance in the transportation and logistics sector represents a crucial step towards operational optimization. Insaite, with its AI-based solutions, emerges as a strategic ally for these companies. Its advanced tools offer a proactive view of maintenance needs, enabling early detection of potential faults in key assets.

Integrating artificial intelligence into predictive maintenance not only reduces operational costs by avoiding unscheduled stops and emergency repairs but also ensures greater reliability in the supply chain. This translates to a significant improvement in safety by preventing potential incidents.

In summary, the combination of predictive maintenance and artificial intelligence provided by Insaite not only transforms how assets are managed in transportation and logistics but also enhances companies’ ability to stay ahead in an increasingly competitive market.

The 5.0 Revolution Is Here

Artificial intelligence plays a fundamental role in the industry’s evolution. As it continues to develop, we’ll likely witness further changes in production and consumption.

Companies embracing AI now will be better positioned to leverage the opportunities offered by Industry 5.0.

In the case of Insaite, we guide you at every step to take your company to the next level with artificial intelligence.